Hello there, do-it-yourself enthusiasts! Is your portable generator giving you problems? Fret not as I’m here for backup.

Nothing can be more frustrating than having equipment that isn’t functioning correctly but don’t worry as we’re about to unravel this issue right now! In fact, decoding problems with your portable generator will soon become second nature once we’ve gone over everything in detail.

This informative article is designed for those who want a deeper understanding of how their power source operates by taking them through an effective process of diagnosing and fixing problems.

From common symptoms to troubleshooting we’ll explore everything together. So let’s get down to business and make sure that your portable generator performs flawlessly moving forward!

Understanding The Anatomy Of A Portable Generator

As someone who enjoys DIY projects, no doubt you value having access to backup power during times of need, thanks to your trusty portable generator. While these machines provide great benefits they can be intricate devices. iI pays off being able to decipher their inner workings when troubleshooting faults or deficiencies occur.

The basic anatomy of any typical portable generator consists of two fundamental parts: namely, its engine whose purpose is generating electric current and its fuel delivery mechanism without which it cannot do so successfully.There’s also an alternator that converts mechanical energy into electrical, a control panel helpful for output regulation, an exhaust system to expel hazardous heat, and the battery which is vital for energy storage purposes.

Identifying Common Problems

Now that we’ve gone over exactly how portable generators work, it is time to discuss some common problems people run into when using these devices. While these generators are mostly reliable so long as they receive regular maintenance attention, ultimately, some problems cannot be avoided entirely. Here are two of the most commonly sighted examples:

Perhaps one of the biggest headaches can come from generators not wanting to start properly in the first place.

There are a number of reasons why this might be happening, such as a faulty spark plug, air filters that have become clogged fuel levels that have run low or old stale fuel gumming up the works, or even issues with the ignition switch itself. Your best bet is usually to start off trying to swap out the spark plug and clean those filters while also ensuring you’re not running low on fuel. If those steps didn’t solve the issue, then try investigating whether your ignition switch is at fault.

Another potential problem that can occur is when your generator starts stalling out or surging unexpectedly – obviously this can be quite inconvenient! This kind of behaviour could stem from a multitude of causes including carburetors getting clogged up bad gas in your fuel mixtures malfunctioning governor mechanisms, dirty filters and/or arrestors – basically all kinds of contamination problems.

To remedy this problem check over everything carefully. Try cleaning or replacing that carburetor and tweaking your governor settings as required. Are there any dirt buildups in the fuel filter? Is there any defective ignition coils? Finally, don’t forget to clear out dirt from your spark arrestors as needed.

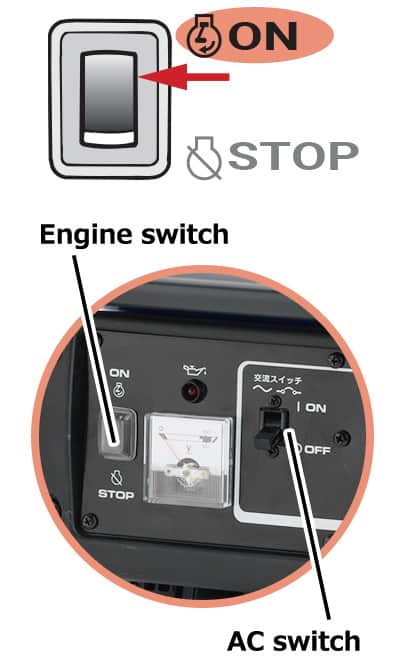

When your generator isn’t producing sufficient power output, there could be any number of causes at play. Some of the most common culprits include damaged control panel switches, loose electrical connections, faulty internal wiring, a weak ground connection, overloaded circuit breakers, or low oil levels in the engine crankcase.

To begin troubleshooting this problem, start by carefully examining all switches on the control panel to confirm that none are stuck or otherwise malfunctioning. Next, take a close look at any electrical connections within the generator and tighten any loose ones as required.

Be sure to also inspect internal wiring for signs of damage or wear and tear that could rob power from your generator. Additionally, pay attention to grounding connections – if any are loose it can lead to irregular performance at best.

If these steps don’t resolve your power output problems, proceed with resetting circuit breaker panels as necessary and/or checking oil levels in engine crankcase – adding more oil if needed to keep levels within manufacturer specifications. But if you’re feeling uncertain about how best to proceed with repairs or maintenance yourself, don’t hesitate to reach out for professional support. It is always better to be safe than sorry.

Diagnosing Electrical Problems

Is something off with your portable generator? Electrical problems could be at play here—and they are usually easier than mechanical ones! Begin troubleshooting by examining its power cord in detail—is it firmly plugged in? Is there any noticeable harm done?

If nothing alarming shows up here next examine your circuit breaker/fuse box closely: have any switches tripped recently? Resetting ones that have should help resolve most problems. For less typical issues, however, check your spark plug for any corrosion or damages that might prevent effective fuel ignition.

And lastly, inspect all fuel lines thoroughly to ensure proper start-up and smooth use. Spare yourself from possible future headaches by thoroughly checking all connections and ensuring there is no debris or dirt buildup before igniting your engine once again. A little bit of prevention can go a long way by saving you unnecessary frustration down the road.

Looking forward, let’s move onto discussing how to troubleshoot fuel problems subsequent to examining electrical diagnosis.

Troubleshooting Fuel Problems

If you’re finding that a lack of power output from your portable generator is becoming an increasing burden for you, there is a high chance that its related to fuel problems.

Firstly, make sure there’s enough gasoline in your fuel tank, if not you’ll need to check both lines leading out of it for any potential blockages or leaks before proceeding further. Once satisfied with those two aspects, turn your attention towards examining the carburetor – known for being prone to getting clogged up with dirt buildup and debris over time resulting in less effective gas input into the engine.

Utilize carburetor cleaner along with a small brush where required (ensuring no leftovers!) before taking things back into operation mode by starting up once again after reassembling everything correctly and keep safety precautions on point every step of the way! As we continue our journey through troubleshooting common generator problems, here’s an imperative rule of thumb: never neglect proper supervision while your generator is running.

Without further ado, let’s move forward with our next step – thoroughly examining the battery and pinpointing any obstacles standing between you and seamless operation.”

Checking The Battery

Having established a foundation for tackling fuel problems in your generator, let’s progress forward to another possible root: the battery. When facing difficulties jumpstarting your machine, examining the battery becomes crucial.

First off, assess whether there’s any corrosion on its terminals. As oxidation impedes power flow and prohibits startup functionality, promptly remove any buildup with either a wire brush or baking soda-water solution blend if necessary.

Next up: turn attention onto investigating connection points in the charging system itself for optimal performance. Ensure all wires are firmly seated at both ends between generator and battery components accordingly. Also pay mind that proper tensioning of an alternator belt is necessary so not to impede functioning capabilities further.

Finally, if nothing appears awry after these tests have taken place thus far -proceed onward into scoping out ignition mechanisms.

Examining The Ignition System

Portable generators are lifesavers for those times when power isn’t available. However, one common hiccup with these devices is a faulty ignition system that can cause low performance and excessive fuel consumption – among other problems. To help discern any potential problems with your generator brush up on these basics:

- Spark Plug: The ever important spark plug ignites the air/fuel mixture in your engine for optimal results.Take care to make sure there are no faults like incorrect gaps or weak sparks.

- Ignition Coil: Without sufficient voltage from this component to generate sparks expect less than stellar outcomes. Check regularly for short or open circuits.

- Magneto: This powerhouse component generates magnetic fields to fuel your generators ignition system – so don’t overlook it! Faulty electrical connections here can cause headaches.

- Be sure to keep up with regular maintenance like checking spark plug gaps and electrical connections.

With these components in good working order your generator will be ready whenever you need it most. Running your portable generator smoothly means paying attention to every component of its ignition system. Begin by checking that your spark plug is secure and undamaged. Then examine whether your fuel filter needs cleaning or replacing. The strength of sparks produced by your ignition coil should also be tested before use as it may affect overall performance without proper maintenance of this part.

Neglecting any defects in these parts could create serious problems for power generation later down the line. Therefore, it is important that you conduct thorough inspections regularly while replacing/repairing faulty pieces promptly, if you want hassle-free use of your machine over time!

Once everything checks out alright, only then should you clean out all other filters required for optimal functionality – starting with air filters.

Cleaning The Air Filter

As part of your portable generator maintenance routine lets take some time now to clean one vital component – the air filter. Regular cleaning is essential in preventing dirt particles from entering the engine through the incoming airflow while maintaining its performance over time.

A dirty air filter can cause problems such as decreased engine performance and fuel economy if left unattended or even lead to damages in other parts of your machines engine system. To start off with cleaning your air filter effectively, gently remove it from its compartment without causing any physical damage that could reduce efficiency levels significantly.

With care taken during removal use compressed air or vacuum cleaner to remove visible dirt particles off its surface. Next up is washing with soapy water using a soft bristle brushcloth without over saturating it with water. Finally, leave it to dry thoroughly before reinstalling back into its compartment.

Done correctly cleaning your air filter helps your generator maintain optimal performance. Now you can move ahead confidently and adjust the carburetor without worries!

Adjusting The Carburetor

The hum of a portable generator is music to some peoples ears, unless that hum becomes a whine or stuttering sound instead! If that sounds familiar then read on: adjusting the carburetor could put things right again without breaking the bank on costly repairs.

Start by securing all nuts and bolts tightly so there are no leaks or loose parts that could interfere with performance. Check all air filters; blockages here mean your generator may not make efficient use of fuel.

Lastly, get that choke setting perfect – too much air and you’ll be dealing with a rich engine, too little and you risk running lean.

With these adjustments?

You’re sorted! For extra mileage consider upgrading any parts that show signs of wear.

Replacing Worn Parts

There is nothing quite as frustrating as struggling with a malfunctioning portable generator for hours on end – but fortunately there are steps you can take to diagnose and fix the problems. For starters replacing worn out parts is often an effective solution.

Begin by checking the spark plug for any visible damage or signs of excessive wear. If it looks like it has seen better days purchasing a new one may be necessary. Additionally, give other components like the carburetor and air filter a thorough inspection. Any damage or wear should prompt replacement as well.

When buying replacement parts, prioritize compatibility with your specific make and model of generator – this ensures proper fit and optimal performance. With any necessary repairs complete don’t forget about preventative maintenance measures that will keep your portable generator running smoothly in future use.

Preventive Maintenance

Your portable generator isn’t something to neglect when it comes to proper care and maintenance. One of the best ways to keep it functioning at its peak is through preventive measures taken on a regular basis.

You don’t want to be caught off guard when an emergency arises only to discover that your generator won’t work correctly due to neglecting its upkeep. Monthly maintenance starts with checking all connections between various parts of the generator for security and any signs of damage or corrosion, and tighten loose parts as needed.

Next on your checklist: inspecting oil levels – if low replenish accordingly – followed by cleaning or replacing your air filter if required.

Lastly, but just as importantly: regularly checking other fluids such as coolant and fuel for their optimum levels. Top them up if necessary so you can feel confident in knowing it’ll be successfully operational when needed most.

Frequently Asked Questions

How Often Should A Portable Generator Be Serviced?

Portable generators are practical backup power sources during emergencies or outdoor activities such as camping or tailgating events. However, using a neglected and poorly maintained one can be hazardous both to human lives and property damage.

To guarantee safe operation without unexpected interruptions caused by malfunctions, it is advisable to perform regular maintenance checks usually once a year as recommended by most manufacturers. This is especially important if you rely on your generator for long term use or in extreme weather conditions.

To ensure optimal servicing level, it is best to follow the manufacturers specific guidelines as different brands may have varying procedures. Some generators may need a thorough assessment due to their higher wattage capacity or frequent usage. By doing so you can avoid costly and preventable breakdowns that could affect your productivity and safety.

How Much Does A Portable Generator Cost?

Anyone considering investing in a portable generator invariably faces one crucial question – what is the cost?

Unfortunately, there’s no easy response since various elements determine its price such as its size and specifications required.The price point for generators can fluctuate from approximately $400 up until beyond $2k – depending on individual preferences and power needs.There are ways of securing better pricing through research including evaluating deals across various stores.

Ultimately,it’s an individual choice that considers both budget constraints& personal preferences.

What Type Of Fuel Does A Portable Generator Run On?

If you’re considering buying a portable generator but don’t know which type of fuel source is best for you yet – fret not! You can opt for either gasoline or diesel models if sticking with traditional options suits your needs best.

But if eco friendliness is appealing then perhaps check out solar powered models instead?

Regardless of what type of fuel source works best for your preferences or needs, though, keep an eye out on any local costs or availability concerns!

How Do I Know When My Portable Generator Needs Maintenance?

Maintaining your portable generator is paramount for its continued efficiency and durability. However, detecting the right time for upkeep can be challenging as an owner.

An unusual start up process, an unstable motor function or excessive exhaust release could be clear indicators that the system needs attention. Remaining alert to any drops in oil levels is equally important as it may suggest a requirement for repair or replacement services.

To avoid any untimely breakdowns refer to your manufacturers recommended maintenance schedule with constant adherence.

The efforts invested presently will pay dividends over time.

What Safety Measures Should I Take When Using A Portable Generator?

Power outages can be frustrating situations. hence, owning a portable generator can be useful in such scenarios! However, to avoid accidents while using one, make sure you follow these safety measures diligently. Read and comprehend the operations manual before switching on the apparatus. Place the machine at a safe distance from windows or doors since its emissions contain hazardous carbon monoxide gas. Use sturdy cables rated for outdoor connection and examine their condition before linking them with your device.

Lastly, for added security purposes, keeping the unit outside in an adequately ventilated spot is highly recommended.

Conclusion

Sometimes, we all need an extra jolt of power – but relying on standard electrical sources may not always do the trick! Portable generators offer an excellent solution. However, they are complex machines that require diligent maintenance efforts on our part. Fuel type is essential information as is estimating ongoing costs that may accrue with use over time. Understanding how often servicing should occur will ensure longevity too! Safe operation requires vigilance too so don’t skimp out on that aspect.

Remember, its essential to take proactive steps now in order to ensure your portable generator runs smoothly and reliably for years to come. And know that you can always reach out for professional advice if needed! With time patience, and commitment owning a portable generator is definitely a feasible and highly rewarding prospect.